Try the beta version of the graphical hardware configuration for miniHIL and let us know what you think!

Hardware-in-the-loop (HIL) is a technique that is used for testing complex real-time embedded systems. Real-world testing of embedded control systems can be complex, expensive, and hazardous. HIL simulation lets engineers efficiently test embedded systems in a virtual environment. A HIL system must emulate sensors and actuators to interface the system under test with the environment. The key benefits of HIL testing are:

Since HIL testing allows to find problems at an early stage, the cost for fixing them drops significantly. However, full-blown HIL systems can be complex and expensive. Hitex in cooperation with Protos has created an affordable system for automated tests.

Use cases:

Environment simulation:

Bus simulation:

Test and Simulation for Motor Control Software:

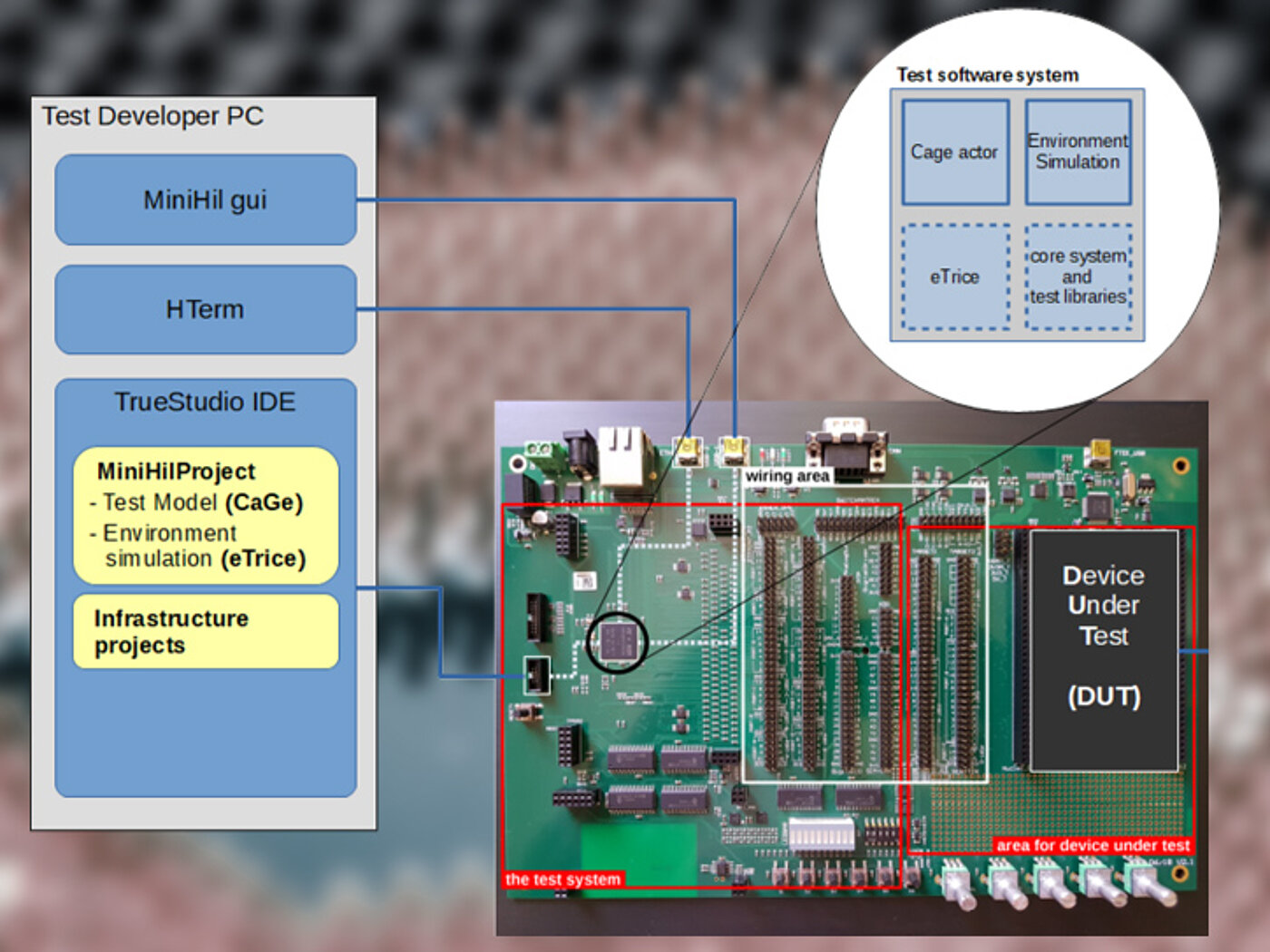

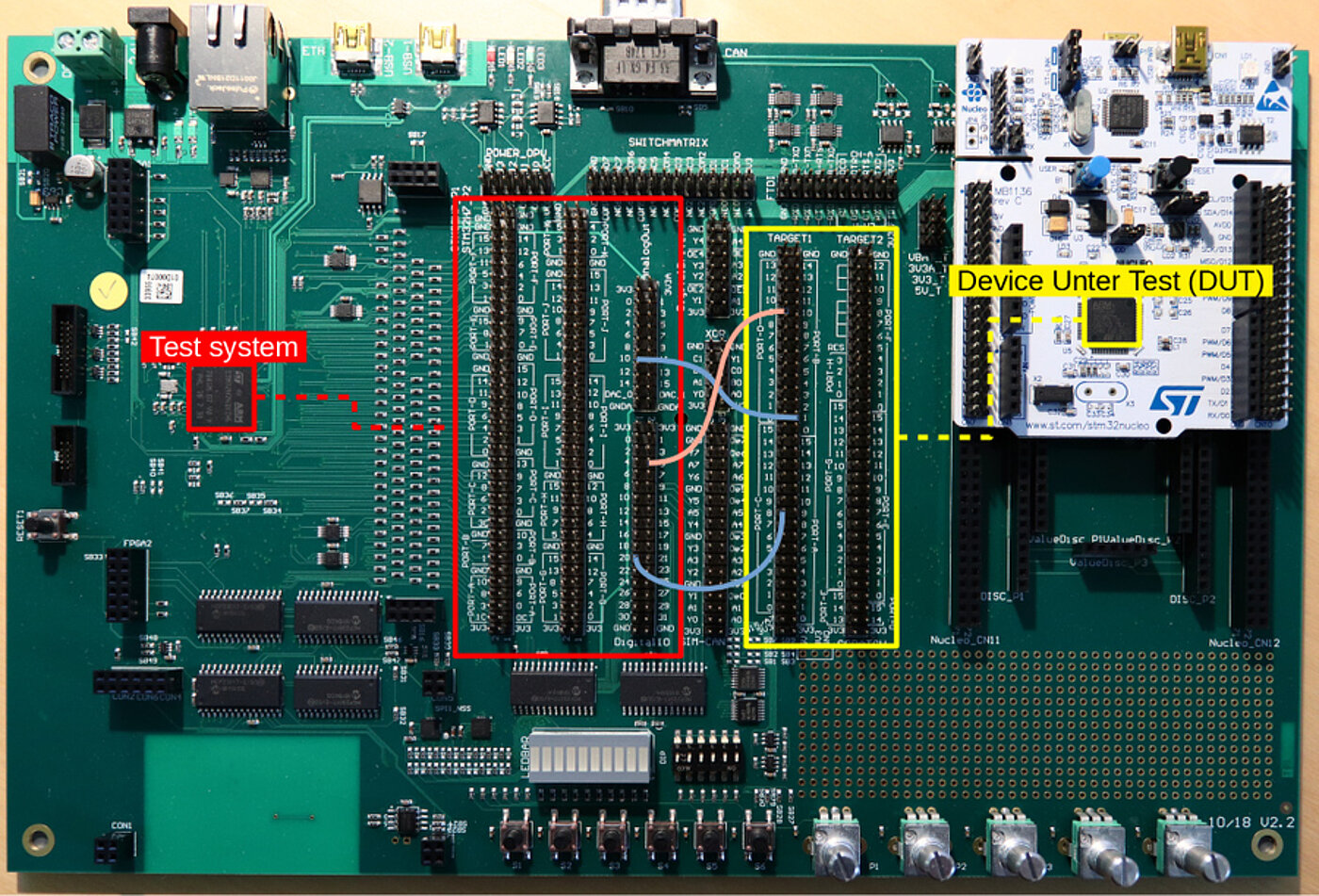

A test hardware (system test/miniHIL) is available for tuning and testing the hardware under test. The device under test (DUT) is connected to the system test/miniHIL. A variety of target adapter boards for various microcontrollers is available for the system test/miniHIL. Of course proprietary hardware can also be connected via custom adapters. Hitex can assist in design and development of specialized interface boards.

The system test/miniHIL base is equipped with a powerful microcontroller performing the stimulation in real time with the above-mentioned simulations and protocols. For particularly real-time critical signals (e.g. SPI slave), an optional FPGA board is available.

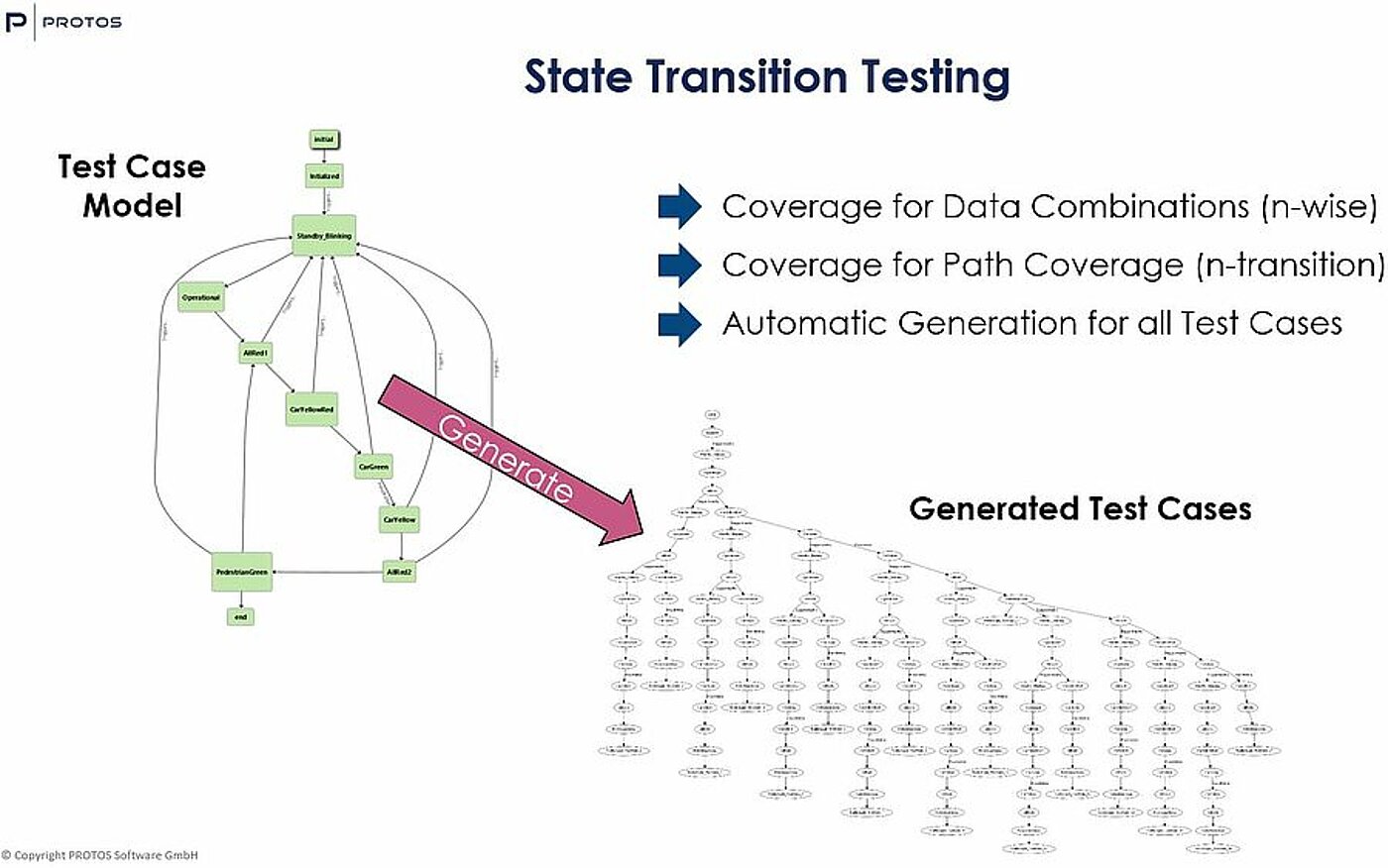

A comprehensive test suite controls the system test/miniHI. The test software makes the hardware signals available in form of model-based adapters. The complete testing environment is defined in a graphical environment. For each PIN of the system test/miniHIL there is a port with protocol in the model, which can then be accessed comfortably by the test creator. In order to create the tests, models such as state machines are available. For complex systems such as engine simulations, Simulink models can be integrated.

These models are controlled using the CaGe test language. CaGe allows the definition of test suites, test sequences and test steps. Once the complete test setup is defined, the code for the test system can be automatically generated and downloaded into the sytem test/miniHIL.

The tests can then be carried out specifically from the test environment or completely automated. Test results are logged.